Current Status and Development Trends of Petroleum Drilling Engineering Technology

Current Status and Development Trends of Petroleum Drilling Engineering Technology

Blog Article

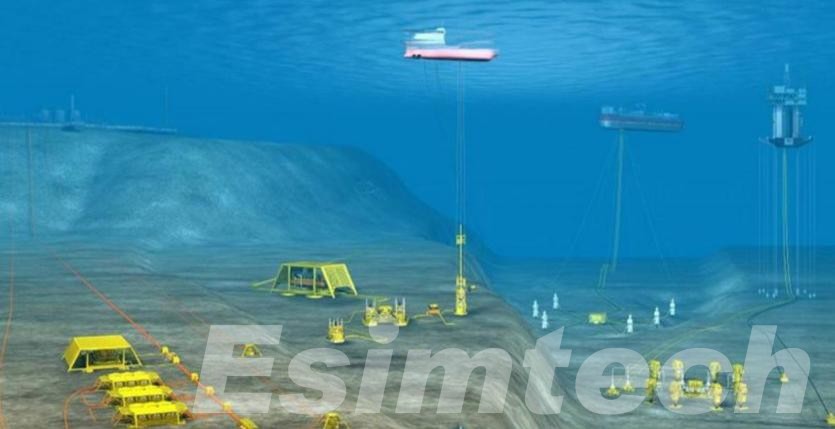

With the continuous increase in demand for oil and gas resources, the pace of offshore oil and gas development is also getting faster, and the deep sea has become the focus of offshore oil and gas development. Underwater subsea oil production system is an offshore oil and gas field development technology that is relative to surface mining technologies such as fixed platforms and floating production facilities. It arranges production manifolds underwater, places some or all multiphase pumps, separators and other process equipment, underwater communication control facilities, and submarine pipelines to connect the extracted liquid back to nearby underwater/surface support facilities or onshore terminals for processing. Throughout the entire production process, monitoring and control are carried out by the main control station of the surface facilities through underwater umbilical cables and control equipment.

The underwater production system has become an inevitable model for future oil and gas development due to its significant advantages:

The underwater production system has become an inevitable model for future oil and gas development due to its significant advantages:

(1) strong adaptability, able to adapt to different water depths, and not affected by the harsh natural environment at sea;

(2) Small footprint, with a large number of devices installed on the seabed, greatly saving the platform's load and footprint;

(3) Reduced or even eliminated its reliance on surface and onshore treatment facilities, breaking through the limitations of long-distance oil and gas transportation;

(4) Greatly improved the recovery rate and development speed of oil and gas fields;

(5) High efficiency, high safety, and good economy.

At present, the key technologies of subsea production systems are mastered by countries such as Norway, the United States, and Brazil. Compared with foreign offshore oil and gas development, China's offshore oil and gas development started relatively late, mainly concentrated in shallow waters within 300 meters, and deep-sea technology lags far behind the international level. In recent years, deep-sea development has become a development strategy in China, with a deep understanding and mastery of the application and development of subsea production systems aimed at laying the foundation for further technological breakthroughs and research and development work.

Traditional underwater production system

Underwater wellhead and Christmas tree system

The Christmas tree is a fundamental component of subsea production systems, serving as a control channel and monitoring equipment for underwater production. The traditional underwater production system uses an underwater Christmas tree to collect the extracted materials from multiple oil wells through an electric submersible pump and pipeline, and directly transport them to the water surface without any treatment.

The underwater wellhead mainly includes casing, casing heads, etc., which are used to support the production tree and fluid flow in the lower part of the wellhead. The Christmas tree generally includes the tree body, connectors, valves, permanent guiding foundation, inner and outer caps of the Christmas tree, and control system. The structure of underwater Christmas trees is much more complex than that of onshore Christmas trees, and they are divided into vertical Christmas trees and horizontal Christmas trees according to the position of the valve group.

The main difference between the two types of Christmas trees is that the valve is oriented in a different direction relative to the production tubing at the wellhead. The control valve and suction valve of the horizontal Christmas tree are kept perpendicular to the production tubing column hole, and the top and bottom of the tubing hanger are surrounded by lateral holes for circumferential sealing; In addition, horizontal Christmas trees can adapt to large-diameter oil pipes and joint devices, making maintenance easier in the later stage. They are also more time-saving in well repair than vertical Christmas trees, and are therefore widely used.

The choice of Christmas tree should be comprehensively considered based on various factors such as the characteristics of the oil and gas field, underwater environment, and operating habits. The key issues faced in designing and manufacturing Christmas trees are pressure bearing, sealing, insulation, and thermal insulation.